Prior to independence, Jute used to be Bangladesh’s major export commodity. However, recently all state-owned jute mills have been closed due to concurring losses. A beacon of hope is the invention of jute cellulose bags that can replace polythene bags.

Jute, also known as the ‘golden fibre’ of Bangladesh, is a versatile, affordable and biodegradable product. Bangladesh is the second largest producer of jute in the world. Before independence, jute used to be Bangladesh’s major source of export earnings.

Jute & Jute Bag Industry at a glance

$

0

M

Potential market size by 2027

10.4% CAGR

Compound annual growth rate

1% of GDP

Contribution of Jute Industry

3,000,000 Small Farm Households

Produce jute in Bangladesh

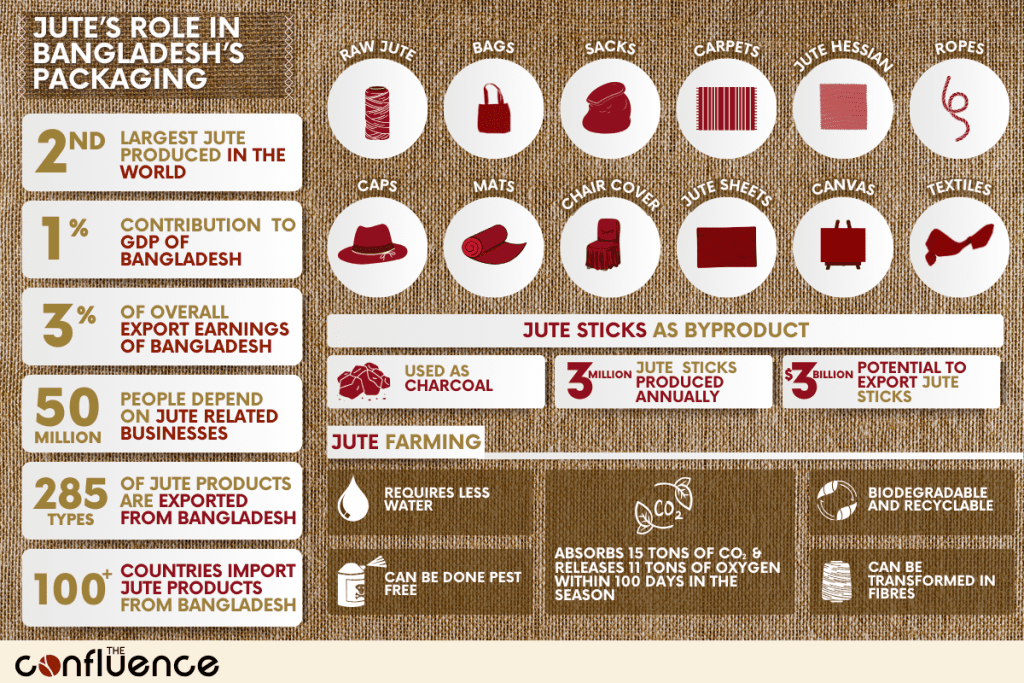

According to research by IMARC Group, the market size of jute bags has the potential to reach $3.84 billion by 2027, with a CAGR of 10.4%. The jute industry contributes 1% to the GDP and 3% of the country’s overall export earnings in Bangladesh. Jute is a vital cash crop for over 3 million small farm households and it is Bangladesh’s largest agricultural export commodity. The livelihoods of around 50 million people depend on jute related business.

Jute Export at a glance

3% of Export Earnings

Contribution of Jute Industry

33% of World’s Jute

Produced in Bangladesh

100 Countries

Exported to

285 Jute Products

Exported

Bangladesh exports jute products to more than 100 countries around the world. These countries include Australia, Brazil, China, Germany, Indonesia, Ivory Coast, India, Pakistan, the Republic of Korea, Russia, the United Arab Emirates, the United Kingdom, the United States and Vietnam etc. Bangladesh exports around 285 various jute products to the world market. These products include raw jute, bags, sacks, carpets, jute hessian, ropes, caps, mats, carpet backing cloth, chair covers, jute sheets, canvas, pulp and paper, non-woven textiles and household products etc.

Benefits of Using Jute

Pest-free | Biodegradable | Recyclable

15 Tons of CO2

Absorbed in 100 days

11 Tons of Oxygen

Released in 100 days

Jute production needs even less water per hectare of land than cotton. Jute cultivation can be done in a pest free way and it mitigates soil problems in the field. One hectare of jute plants can also absorb about 15 tons of carbon-di-oxide from the atmosphere and release around 11 tons of oxygen within the 100 days in the jute-growing season. Moreover, jute is totally biodegradable and recyclable. Jute is also an energy efficient option as it can be transformed into jute fibres using fewer resources.

Charcoal Production as Byproduct

0

M

Jute sticks produced annually

90% of Bangladesh’s Jute Production

Exported to other countries

3 – 3.5 Million

Export potential of charcoal

Moreover, jute sticks produce charcoal products as a byproduct. Currently, Bangladesh produces around 3 million jute sticks annually. Thus, our country has the capability to export this charcoal worth 3 to 3.5 billion. Jute tin is also thought to be more durable than metallic-tin. More research is needed to discover its further potential. Bangladesh is currently producing 33% of the world’s total jute and exporting 90% of the produced raw jutes.

With the growing use of harmful products, like plastics and polythenes, the increase in use of jute products is getting mandatory day by day.

Current Situation Regarding the Use of Plastics and Polythenes

The use of polythene and plastic is extremely harmful for our environment. Plastic bags take around a thousand years to decay into the soil.

646 Tons

Daily plastic usage in Dhaka

646 821,250 Tons Annual Plastic Waste in Dhaka

40% recycled | 60% pollutes

2.47% of Global Plastic Pollution

Contributed by Dhaka

Recently, Dhaka uses around 646 tons of plastic daily, while the country generates approximately 821,250 tons of plastic waste. But, only 40% of this waste is recycled or reused, and the remaining 60% plastic pollutes the environment. The “Environmental Performance Index-2022” highlights that Bangladesh accounts for 2.47% of the total plastic pollution worldwide. Still, Bangladesh ranks fourth among countries that are falling behind in pollution prevention efforts.

Government Initiatives for the Restrictions on the Use of Plastics and Polythenes

The government of Bangladesh imposed restrictions on the use of polythene in 2002, as the first country to do so in the world. In the absence of jute products, the law was implemented by the surge in use of biodegradable products.

The government had also established the law on the use of jute sacks in 2010. But it was disregarded due to the ignorance of common people.

On September 26, 2013, the ministry of textiles issued a circular on mandatory use of jute bags for commercial packaging of rice. It instructed the traders to stop using polythene/plastic bags by December 2014. But the circular was unsuccessful as well.

2897 Campaigns

Conducted by Department of Environment between 2015 and 2021

5954 Cases

Registered during operation

BDT 208.1 Million

Fined for non-compliance

According to the Department of Environment, a total of 2,897 campaigns have been carried out from 2015 to 2021 in order to rule out the use of polythene bags. A total of 5,954 cases have been registered during the operation and a fine of BDT 208.1 million has been realised in these cases. Out of which, BDT 176.9 million has been collected. Around 91 people have been sentenced to various terms of imprisonment for using polythene.

A High Court rule banning the use of plastic bags from coastal areas, hotels and restaurants was issued in 2022.

0

M

Jute sacks produced yearly

One reason for this failure might be the inconvenience related to jute packaging. Moreover, the insufficient supply chain and affordability also played a crucial factor here. It is not clear whether there has been any improvement in availability of jute sacks lately. A report published in February, 2023, stated that Bangladesh Jute Mills Corporation (BJMC) is in a situation to double its production of jute sacks from the existing 200-250 million pieces a year, if the market demand grows.

Challenges in the Jute Sector

0

%

Export slump in July-February

In spite of the possibilities regarding jute products, there is a sharp decline in the export figure of jute products. Jute and jute goods exports slumped 24 per cent year-on-year to $610 million in the July-February period of the current fiscal year.

Recent EPB statistics reveal that export earnings from jute products were recorded at $1.13 billion in FY22. But it decreased by 19% in FY23 and turned to $912 million.

Jute Products Export

- FY 221130 Million

- FY 23912 Million

- FY 24 (July-Feb)610 Million

On the other hand, export earnings of jute yarn and twine have decreased by 28.64% to around $498 million in FY23. Whereas, the amount was around $698 million in FY22. Raw jute export income also decreased by 5.5% to $204 million in the same fiscal year. Only, the export income from jute sacks and bags increased by around 8% to $109 million in FY23, considering the income of the previous year. Several reasons can contribute to these challenges.

28.64% decrease in FY 23 | $498 M

Jute yarn and twine exports

5.5% decrease in FY 23 | $204 M

Raw jute exports

8% increase in FY 23 | $109 M

Jute sack and bag exports

The anti-dumping duty imposed by the Indian government ranges from $19 to $352 per ton through a tariff notification. Due to this reason, Bangladesh had to shut down many jute mill operations. This is one of the reasons for the lag in the jute industry.

Being a large economical market in Bangladesh, the Russia-Ukraine war affected the jute export. The war in Sudan has affected shipments as well. As a result, the market price of jute has increased and seen volatility.

0

X

Jute bag demand increased

Bangladesh has a low jute production capacity. During 2023, Bangladesh held around 72 per cent of the entire global export earning from jute. On the other hand, the demand for jute bags increased to 700 million from the existing 100 million. But Bangladesh is unable to meet the demand.

Moreover, gas and electricity tariffs increase the production cost. This is a major reason for the backlash in jute export.

There is a prevalent case of corruption in BJMC. Restructuring of BJMC and encouragement of Public Private Partnership can help increase investment in the jute industry. Lack of skilled workers, fragmented lands, lack of better quality seeds also pose threat to the jute production.

Initiatives Taken To Restore the Jute Industry

Mandatory Jute Packaging Act 2010

To develop the jute industry, the current government imposed the ‘Mandatory Jute Packaging Act-2010’ and ‘Mandatory Jute Packaging Rules- 2013’. The acts came into implementation from 1st January, 2014.

6 Products for Mandatory Jute Packaging

Paddy, rice, wheat, maize, fertiliser, sugar

11 More Products for Mandatory Jute Packaging

chilli, onion, garlic, turmeric, ginger, pulses, coriander, potato, atta, maida and rice bran

In 2015, the government made jute packaging compulsory for six products. Those are paddy, rice, wheat, maize, fertiliser and sugar. After the imposition of anti-dumping duty by India on Bangladesh jute and jute goods, the government added 11 more products, chilli, onion, garlic, turmeric, ginger, pulses, coriander, potato, atta, maida and rice bran, in the list of mandatory jute packaging.

500

M

Annual demand for bags in cement industry

The textiles and jute ministry took initiative in 2017 to make the mandatory use of jute bags in packaging cement. The goal behind this was to boost domestic use of jute goods as the cement sector needs 500-600 million of bags a year. The yearly production of cement was 25 million tonnes by 35 cement factories. But the cement manufacturers deemed this decision to be unrealistic, unwise and it would increase the cost of packaging.

Low-Cost Loan Policy

0

%

Interest Rate

BDT 100 billion

Anticipated investment

2.5 % Interest

To be borne by the state

20-year

Revolving fund

In 2018, the jute ministry took an initiative to form a policy to provide low-cost loans for the jute workers. The ministry was willing to invest BDT 100 billion for the purpose of this project. The draft proposed that the government should form a 20-year revolving fund based on the budgetary allocation to provide loans to farmers, traders, industrialists, diversified goods producers and exporters. The loans were supposed to be disbursed at 5 percent interest, among which, half of the interest payments would come from the state offer as subsidy. Bangladesh Bank was designated to manage the fund. Only the licensed farmers for jute and jute goods business will be eligible for getting loans from the fund in this project. The same year, the government took steps to modernise jute mills as well.

Production of Plastic-like Jute Bags

0

Days

Biodegradation period after disposal

In July, 2019, Dr. Mubarak Ahmad Khan also produced plastic-like bags made from jute. Jute fibres could be turned into low-cost biodegradable cellulose sheets and then further transformed into greener throw-away bags that feel like plastic. The bags are biodegradable within three months after being buried in soil and are also recyclable. In February 2024, a project worth BDT 1 billion has been taken for upscaling of the project.

pilot project

2000 Bags / Day

Produced under pilot project

$900,000 Funding

Provided from climate change trust fund for upscaling

Bangladesh produced 2,000 bags per day as an experiment in 2019 and planned to scale up commercial production after signing an agreement with the British arm of a Japanese green packaging firm. The same year, the government approved around $900,000 in funding from the country’s climate change trust fund to aid the large-scale production of the bags.

Restoration of Closed Mills

0

/25

State-owned closed jute mills to be leased

On 1 July 2020, the government closed all the state-owned jute mills due to the excessive losses. In January 2021, the government floated the first international tender to lease out 17 of the 25 state-owned jute mills. Among them, five jute mills have resumed their operation with an investment of around BDT 4 billion. According to the tender, a lessee can use the jute mill premises only to produce jute goats and jute-related products.

৳

0

B

Invested to resume five jute mills

During 2021 big conglomerate companies including Pran, Bay and Akij groups wanted to get leases of state owned jute mills. Moreover, three private-sector entrepreneurs have been selected for three jute mills in Khulna and Chattagram zones. Four H Apparel is selected for leasing out Mills Furnishing Limited; Uni World for Doulatpur Jute Mills, and Akij Jute Mills for Jashore Jute Mills. The mills will be handed over after the entrepreneurs pay 24 months’ rent to the BJMC.

Around 20 months after shutdown, the state-owned jute mills have been given a new lease of life in order to start operating. Bangladesh Jute Mills came into operation on a limited scale on 26 February, 2022. The joint initiative of Bay Group, TK Group, Bestla Limited, Taiwan Shoe Materials and BN Trading contributed to this initiative. The Jute Alliance will primarily invest BDT 3 billion in the mill and will increase investment gradually.

In January, 2024, Indian companies invested in two closed jute mills to restart the production activities. A Taiwanese firm has also expressed the willingness to invest in another mill under a government initiative. The BJMC has also extended the lease tenure to 30 years. Due to this extension, the private sectors can now produce jute and jute related products with forward and backward linkages.

Distribution of Jute Bags

In April, 2021, the government stepped up to provide free jute bags to 3.3 million first grade students admitted in public, private and Ibtedai madrasas of the country, so that they can attain knowledge about jute products from the initiation of their life. The project will be worth BDT 2.87 billion approximately and each bag will cost Taka 750 to the government. The cost may vary depending on the number of students. The government aims to complete this project by June, 2024.

3.3 Million First-Grade Students

To receive free jute bags

BDT 2.87 Billion

Public expenditure

BDT 750

Expense per bag

Even after the completion of the project, the initiative will keep running in the following years. An attempt will be made to bring the jute bags using the G to G method. This project also aims to increase the use of jute projects and benefit the farmers.

Jute Products Business Promotion Council

By improving internal market management, the government has taken initiative to improve the export of jute products in different countries of the world. To bolster this cause, the prime minister declared jute products as the ‘Product of the Year’ in 2023. The Ministry of Commerce has also formed the ‘Jute Products Business Promotion Council’ to boost the development of this sector. Due to the initiatives taken by the government, the production of jute products has increased a lot in recent years.

Revival Project of the Jute Industry

Initiatives

400,000 Farmers

To receive one kg jute seeds each

BDT 80 Million

To be invested

30% Subsidy

For modernizing jute mill machinery

20% Cash Assistance

For jute products

Waiving off tax at source | Providing low-interest rate bank loans | Adjusting tax rates

In February, 2023, the government of Bangladesh took a decision to disburse incentives for jute production. In order to rehabilitate jute cultivation, the government will provide 400,000 farmers with one kilogram of jute seeds each to dedicate one bigha land to grow jute. Moreover, a total of BDT 80 million will be invested in the project to revive the jute industry. A large portion of designated land for jute cultivation is illegally occupied in our country. This project also sheds light on the solution of this problem.

Providing a 30 per cent subsidy for modernising jute mill machinery, providing low-interest rate bank loans, adjusting tax rates on jute exports, raising cash assistance to 20 per cent for different jute products, waiving off tax at source on export incentives were highlighted as well.

Distribution of Free Seeds

336,600 Farmers

To receive free seeds

A kg of BJRI Tosha Pat – 8 Seeds

Per farmer

In February, 2024, Bangladesh took an initiative to provide BDT 74.9 million in incentives to uplift jute production with an aim to bring back the glory of golden fibre. Approximately 336,600 small, marginal and medium farmers will get free seeds under this initiative. Each farmer will be facilitated with a kg of BJRI Tosha Pat-8 seeds per bigha. The market for jute bags was estimated to reach $2.6 billion by 2022 globally.

The Sonali Bag Project

0

kg

Carrying capacity

In January 2024, the government took up a pilot project to make the private sector aware about the profitability of Sonali bags. Sonali bags are recyclable and made from jute cellulose. Thus, it is environment-friendly. To convince the private sector to produce the Sonali bag, the government has procured a number of machines and bolstered the commercial viability of this idea. ‘Sonali Bag’ or jute bag can be played as an alternative to polythene bags. The authority concerned is trying to develop and promote jute bags suitable for all weather conditions and can sustain a heavy load of around 5 to 6 kilograms.

Investment to Establish Jute Factory

Dr. Mubarak Ahmad Khan, the Bangladeshi scientist, invented a biodegradable and eco-friendly jute bag in 2018. It took around six years to complete the process. This discovery is known as ‘jute polymer’. Jute polymers can get decomposed within 6 hours to 6 months in soil. A great number of national and foreign institutions had expressed their interests in its production. But the jute polymer production project was said to be sealed due to lack of BDT 1.7 billion. Moreover, the project needed a dedicated budget, identity and institution, which was not available at that time. The project had the potential to fulfil one-third of the world’s demand if the total produced jute in Bangladesh could be transformed to ‘Sonali Bag’. Moreover, the fibre strength of jute is 22 times higher than steel. Thus, jute composite has the possibility to replace steel.

Currently, 2 scientists along with 6 workers are producing only 250 jute bags per day in their own factory. These bags are being exported in foreign countries. As a result, the demand of our country remains unfulfilled. Thus, the government of Bangladesh took an initiative to invest 100 crores for the project in February, 2024. With this project, a factory will be established in Demra, Dhaka. It is estimated that this project will be able to produce almost 10 lakhs jute bags per day.

Contribution of the United Nations

UN Member States aim to complete the negotiation of a global deal in order to end plastic pollution with the resolution titled “End plastic pollution: Towards an International legally binding instrument” by the end of 2024. This resolution also seeks to promote jute products. The United Nations Development Programme in Bangladesh has also introduced jute polymer based biodegradable bags for the UN staff members in Bangladesh during World Environment Day, 2023. This initiative was taken to enhance sustainable practices by setting an example for others.

Recommendations

- The use of jute products can help achieve sustainable development goals. In this regard, mass awareness is necessary. Awareness campaigns on a larger scale can help promote the use of jute products. More action plans, surveys, seminars and promotional activities by the government have the potential to turn the export figure by jute to $100B within 2030.

- The concept of Extended Producer Responsibility (EPR) can be introduced in order to control the plastic use and promote jute products. Manufacturers and producers can come forward for the recycling of plastic products.

- Marketers should be made aware of the market niche of jute products. To increase the practice of using jute products, the pricing strategy should be changed and jute products must be made affordable.

- The government has already formulated the 3R Policy to reduce the volume of waste related to plastic products. But the policy is not yet implemented properly. Steps should be taken to implement this policy soon.

- The entrepreneurs can be facilitated by lowering the commercial bank tax rates to promote the expansion of jute business. The EPB can also organise more international fairs to support the use of jute products.

- The shutdown of several jute mills has created a lag in the jute industry. It must be taken care that such incidents are prevented in the future. Farm mechanisation and improvement of the mode of transportation should also be done.

- Sufficient government purchase centres must be developed near jute producing areas in Bangladesh.

About the Author

Hamim Mubtasim is the Brand Manager at The Confluence. He is currently pursuing his undergraduate studies at the Institute of Business Administration, University of Dhaka. A business student by choice and marketing geek by passion, he aspires to manage big brands someday.