As the Prime Minister of Bangladesh, Sheikh Hasina inaugurates South Asia’s largest and country’s first green urea fertilizer factory on November 12, 2023, this article takes a deeper look into the existing challenges of fertilizer production scene of Bangladesh and how the new plant can potentially abate the agony of farmers as well as consumers.

Bottlenecks

While Bangladesh is on its path to develop major industries and become a manufacturing hub of the world, the country is still an agriculture-based economy. The fertile lands, environment and all other natural amenities make the country a perfect place for agricultural production. In this agriculture production process, fertilizer plays a pivotal role as one of the main inputs to increase crop yields. The country’s fertilizer production industry experiences non-exhaustively TWO major bottlenecks.

Two Major Bottlenecks

Inefficiency

In the status quo, most of the country’s fertilizer factories suffer from poor maintenance, gas supply shortages, old machineries, aging of plants and lack of skilled manpower which inhibit them from utilizing the full installed production capacity.

Obsolete technology in these old factories is creating inefficiencies in the production process. Due to old machinery, it takes much more gas than ideally required which results in wastages of gas.

43.72 Million Cubic Feet (MCF)

Bangladesh’s raw material for producing 1 ton of urea.

25 Million Cubic Feet (MCF)

Global standard raw material for producing 1 ton of urea.

As the plants age gradually, they fail to operate all year round and as a consequence the factories lose production efficiency for a lack of maintenance and overhaul. The four state-owned factories require 43.72 million cubic feet (MCF) gas to produce an average of 1 ton of urea whereas other countries use only 25 MCF gas to produce the same quantity.

Reliance on Import

The inefficiencies in the production process cause low domestic production. As a consequence, to meet the growing demand of the fertilizers, Bangladesh has to import from other countries at a higher price. The major portion of the country’s increasing fertilizer demand is met by imports.

Bangladesh’s Fertiliser Demand in FY 2022-23 (Million Tons)

Source: Department of Agricultural Extension

No Data Found

0

Mn

Tons Average Annual Demand for Urea

According to the Department of Agricultural Extension (DAE), in FY 2022-23, the demand for urea fertilizer was 3.4 million tons, DAP 2.4 million tons, TSP 1.04 million tons and MOP 1.4 million tons (1.4 million). Each year, on average, the annual demand for urea fertilizer is around 2.9 million tons. In FY15, the local demand for urea fertilizer was 2.7 million tons while the domestic factories produced only 0.878 million tons. In FY16, the domestic demand for urea was 2.8 million tons while the country produced only 0.213 million tons. (Dhaka Tribune, 2016).

FY 2015

- Demand for Urea in FY 152700000 Tons

- Domestic Production of Urea in FY 15878000 Tons

FY 2016

- Demand for Urea in FY 162800000 Tons

- Domestic Production of Urea in FY 16213000 Tons

Bangladesh is able to produce only 30% of the demand whereas the rest 70% is imported from countries such as Russia, China, Saudi Arabia, Qatar, United Arab Emirates (UAE).

0

%

Of Urea Demand Met with Import

Why is heavy reliance on fertilizer imports bad?

To put it simply, when a country has to rely on foreign sources for a product or service, any disruption or shock at any stage of the supply chain halts the delivery of that product in the importing country. The same happened to Bangladesh’s fertilizer imports. The COVID-19 pandemic and Russian Invasion of Ukraine caused massive supply chain disruptions in the fertilizer supply chain which halted the supply of fertilizers in Bangladesh, pushed demand further and eventually shot up the prices.

To make fertilizers affordable to the poor farmers, the Government of Bangladesh (GoB) heavily subsidizes fertilizers. Regardless of the import prices, the government sells the fertilizers at a lower rate which is affordable to the farmers.

Why are these fertilizer subsidies necessary?

High cost of fertilizers will eventually increase the cost of production which in turn raises the selling prices of food and agro products. Because an increase in price in one input raises the end selling price to the consumers. Thus, this fiscal measure of the government, in the form of subsidies, enables farmers to continue production at an affordable rate and keep the market prices stable.

BDT

0

Subsidy per ton of fertiliser

The government provides subsidies of BDT 12,000-13,000 per ton to deliver the imported fertilizers at an affordable price directly to the farmers. While the importers import urea at BDT 96 per kg, the government sells urea to farmers at a subsidized rate of BDT 16 per kg.

BDT 96 per kg

Import price of urea

BDT 16 per kg

Subsidised selling price of urea

These fertilizer subsidies are aimed to encourage positive externality in the agriculture sector as the benefits of low cost of production for farmers spills over to consumers and the entire market.

Ghorasal Polash Urea Fertilizer Project (GPUFP)

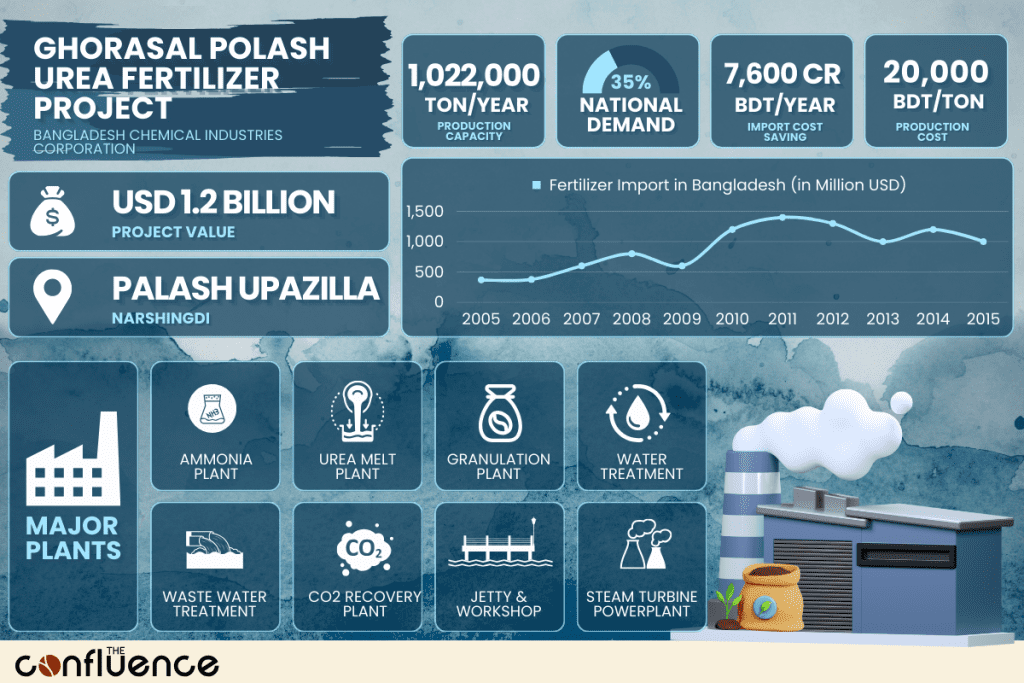

To significantly reduce the reliance on fertilizer imports and facilitate food security in an environmentally sustainable fashion, the GoB has established the Ghorasal Polash Urea Fertilizer Project (GPUFP) at Polash upazila in Narsingdi district. Owned by the Bangladesh Chemical Industries Corporation (BCIC), the fertilizer plant is the largest in South Asia and first green fertilizer factory in Bangladesh. The new factory was built by replacing the previous two factories in Ghorashal and Polash.

Production Capacity of GPUFP

2800 MT per day

1,022,000 MT per year

3.15 lakh tons annually

previous production of fertiliser

On November 12, 2023, Prime Minister Sheikh Hasina inaugurated this environmentally friendly urea fertilizer built on 110 acres of land which has a daily production capacity of 2,800 MT per day and annual production capacity of 1,022,000 MT whereas the previous two factories combined produced only 3.15 lakh tons of fertilizer annually.

$

0

Bn

Project Cost

This project is one of the very few and largest mega projects undertaken by GoB that costs more than a billion dollars. The total expenditure of the project is estimated at BDT 15,500 crore (USD 1.2 billion). In terms of budget, this project is larger than Karnaphuli tunnel or Dhaka Elevated Expressway. GoB financed BDT 4,580.21 crore and the rest BDT 10,920 crore was obtained through debt financing from three foreign financial institutions- JICA, HSBC, and Bank of Tokyo Mitsubishi UFJ Limited.

- GoB Financing4580.21 Crore

- Debt Financing10920 Crore

Two foreign contractors – Japan’s Mitsubishi Heavy Industries Ltd. and China’s National Chemical Engineering No-7 Construction Company – have completed the project by installing state of the art technology.

Major Components of The Plant

- An ammonia plant

- A urea melt plant

- A urea granulation plant

- A water treatment plant

- A wastewater treatment plant (WWTP)

- A carbon dioxide (CO2) recovery plant

- A jetty

- Maintenance workshops

- A power plant consisting of two steam turbine generators (STG) with a capacity of 32 MW each and a gas engine generator unit with a capacity of 9 MW as well as their auxiliaries and ancillaries

The plant requires 28 MW of electricity to run.

Absorbs Carbon Dioxide

This fertilizer factory is the first in Bangladesh to absorb carbon dioxide (CO2), an environmental pollutant, from the flue gas of the primary reformer. By using the CO2 that is captured, the production of urea fertilizer will rise by around 10%.

0

Employment Generation

According to the Bangladesh Small and Cottage Industries Corporation (BSCIC), the urea fertilizer plant is expected to generate employment directly or indirectly for around 30,000 people. To ensure smooth operation of the plant, the government has taken several capacity building initiatives to skill the manpower by providing training from foreign experts. The plant will require BDT 20,000 per metric ton as production cost. The plant is expected to save BDT 7,000 crore in import costs per annum.

BDT 96 per kg

Import price of urea

BDT 22 per kg

Production cost of urea in the plant

৳

0

Cr

Saved import cost annually

The plant will significantly reduce the reliance on imports as combining the factories with all the local factories will together produce 1.9 million MT against the country’s annual demand of 2.6-2.9 million MT urea fertilizer.

Estimated demand and domestic production of urea after operating the new plant

- Demand for Urea2900000 Tons

- Domestic Production Capacity1900000 Tons

Recommendations

- As the other fertilizer factories suffered due to poor maintenance and lack of overhaul, the same experience should not be repeated in this extremely ambitious green urea fertilizer plant built by the government. The plant should be brought under proper oversight and maintenance. Regular inspections of the factory, including the machinery should be conducted by experts. The machineries should be repaired and upgraded whenever it’s necessary.

- Continuous capacity building should be one of the top priorities to make this project a success. Providing the technological and managerial know-how to the workers and managers of the factory on a regular basis is pivotal.

- The factory can be a hub for providing local employment in the Narsingdi district. Thus, the factory should create job opportunities for the local populace while the government bring them under various skill development and capacity building programs.

- Waste management should also be one of the key areas to focus on as reluctant disposal of waste has adverse effects on the environment as well as on humans. A proper waste management system should be put in place and properly implemented.

About the Author

Shah Adaan Uzzaman is the Blog Administrator at The Confluence. A former Bangladesh Television Debate Champion and winner of several policy & debate competitions, he is currently a student of IBA, University of Dhaka.