The Rana Plaza Tragedy showed how little heed was paid to workplace safety in Bangladesh. However, continuous efforts have been made by different stakeholders including the government and NGOs, even though major scope of improvement remains in non-RMG industries.

According to the 2024-25 Labour Market Profile report, currently Bangladesh has an employed population of 71 million, among which 85% work in the informal sector. Every year, around 42% of the national income is contributed by the labourers. With this growing importance of the employed population in Bangladesh, workplace safety has been one of the major issues in recent times. In January, 2024, ILO acknowledged the effectiveness of occupational safety and health frameworks in Bangladesh. Even though many initiatives have been taken over time, the workplace situation still needs to be improved.

0

M

Employed Population

85% Informal Employment

Composition of Employment in Bangladesh

42% Contributed by Labourers

Composition of National Income in Bangladesh

Trends in Fatalities and Global Safety Rankings

Bangladesh has been ranked among the 10 worst countries regarding workers safety by the Global Rights Index of the International Trade Union Confederation from 2017 to 2023. The 2023 ITUC Global Rights Index has indicated a severe lack of workplace safety measures in Bangladesh as well. This is an alarming situation for Bangladesh.

According to the Global Rights Index of the International Trade Union, eight Export Process Zones (EPZ) prohibits forming any labour union. The largest export-oriented sector of the country, the RMG industry altogether employing 4.5 million people, obstructs the formation of any labour union.

There exists a lack of reliable data regarding workplace accidents and deaths. In many cases, violations of labour laws are not reported. However discrepant the different data may be, a look at them will help us understand the situation better.

National Occupational Safety and Health Profile by the Government of Bangladesh

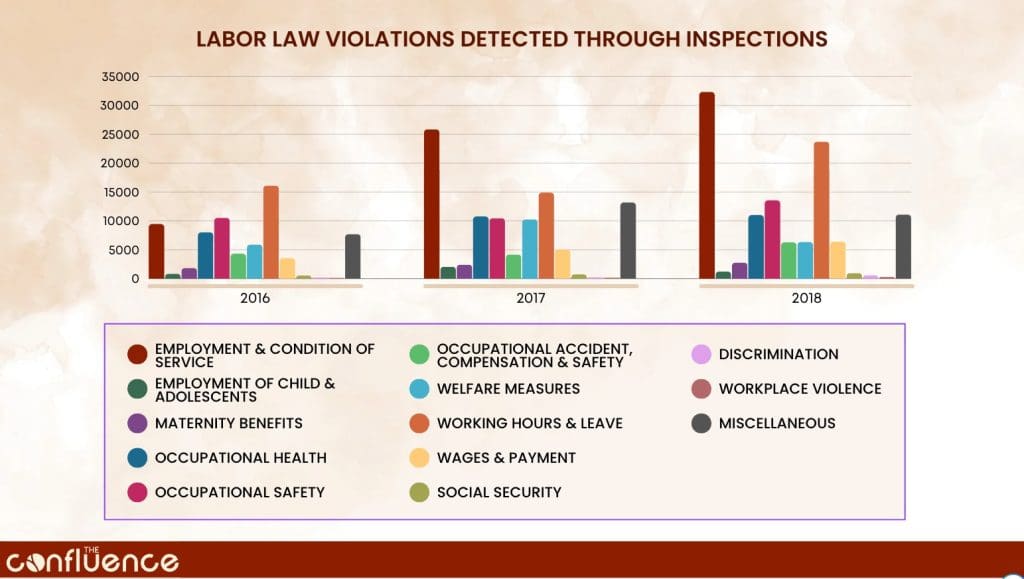

In 2016-2018, the National Occupational Safety and Health Profile recorded 296 thousand violations of labour laws at work. The profile classified labour rights violations under 13 major categories. These categories include recruitment and job conditions, children and adolescent workers, maternity welfare benefits, occupational health and safety and payment of wages.

0

Major Categories of Labour Law Violation

296,166 Violations

During 2016-2018

7624 Deaths and 5332 Injuries

During 2015-2023

99% of the Dead are Male Workers

In 2023

36% in Transportation Sector and 15% in Construction Sector

Concentration of workplace deaths is high in two sectors

Workplace Situation Report by BILS

According to Bangladesh Institute of Labour Studies’ Workplace Situation Report 2023 that was created using newspaper reports of workplace deaths, a total of 7624 workers died in workplace accidents during the 9 years from 2015 to 2023. 99% of the victims of accident who died in 2023 were male workers.

Number of Workplace Deaths

Source: Bangladesh Institute of Labour Studies (BILS)

No Data Found

Majority of the deaths happen in specific industries such as transportation and construction. According to BILS report, in 2023, 269 of a total 742 deaths occurred in the transportation sector, which is 36% of the total deaths. The second highest deaths occurred in the construction sector, consisting of 15% of the total deaths. Two sectors account for over half of the total deaths.

Sector-wise Share of Workplace Deaths in 2023

Source: BILS

No Data Found

Workplace Accident Monitoring Report 2022 by OSHE Foundation

According to a survey of the Bangladesh Occupational Safety, Health and Environment Foundation, at least 149 workers died in workplace accidents in the construction sector in 2023 and many by electrocution. There was a rise by 48% in workplace death in 2023 as well. The report also reveals that at least 329 and 1103 workers died in the formal sector and the informal sector in workplace-related accidents respectively. On the other hand, 502 workers were injured in workplace accidents.

Share of Workplace Death by Formality of Workplace

Source: OSHE Foundation

No Data Found

Bottlenecks in Ensuring Occupational Safety

Workplace safety is compromised for a plethora of reasons. Different industries have different sorts of reasons. Among the 5000 plastic manufacturing factories of Bangladesh, many face problems such as unavailability to open roof access, firefighting drills, and safety tests of machines and electrical facilities. Over 60% factories in Bangladesh are indifferent to crucial safety measurements and proper training. Furthermore, 42% factories don’t have any proper manual for chemical handling. Thus, the workers face safety issues in emergency situations.

Plastic, Leather & Chemical

0

%

Factories indifferent to safety measures and trainings

42% of the Factories

Don’t have proper manual for chemical handling

20-30% of the Injuries

Occur in the chemical section of tanneries

10-15% of the Injuries

Occur in due to poor electrical conditions

45% of the Machineries

Cannot use sensors

According to different statistics, in small, medium and large factories 50%- 60%, 5%-10% and 35%-40% of injuries occur due to the unconsciousness of workers, mechanical problems and carelessness of owners respectively.

In Bangladesh, the leather industry has the potential to provide economic growth for the country. But Occupational Health and Safety (OHS) rules are not properly followed in this sector. The chemical section is the most crucial accident prone area in the leather industry. This area includes chemical storage, chemical distribution, and different leather tanning processes. According to a technical report of UNIDO, around 20% to 30% injuries are contributed by this area. Heavy machinery is used almost in all stages of the production in the tannery industry. But the usage of machinery does not comply with the safety manuals. Sensors are not usable in around 45% of the machinery. Lack of knowledge of proper maintenance is another reason for accidents. The electrical setup is also risky in maximum tanneries. Unplanned wiring, over using load open phase electrical installation etc causes accidents. About 10% to 15% of injuries occur due to the poor electrical condition of the industry .

Female Workers’ Experience

83% of Female Workers at DEPZ

Do not lodge complain after facing sexual harassment

90% of Female Workers at DEPZ

Do not know about the anti-harassment committees

A study by a non-profit organization, Karmojibi Nari, indicates that 83 percent of female workers back out from lodging any complaints on sexual harassment faced at their factories in the Dhaka Export Processing Zone (DEPZ). Female workers refrain from reporting on payment delays or issues relating to maternity leave with the fear of losing their jobs as well. Around 90 percent of the women workers don’t even know about the existence of any safety committees, anti-harassment committees or workers welfare associations in DEPZ. This poses a great risk in the safety of female workers.

Regarding the safety of women from sexual harassment, the amended laws don’t provide any necessary action plan in the factories in spite of the recommendations made by the High Court Division of Bangladesh in Bangladesh National Women Lawyers’ Association (BNWLA) vs. Bangladesh. As a result, no specific regulations have been carried out in this regard.

In July, 2021, the government formed a national committee to suggest short, medium and long-term recommendations to ensure the compliance of local industries with workplace safety standards. But no visible effectiveness has been seen yet.

Another core reason for workplace safety issues is the lack of enough implementation of laws and provisions in non-RMG sectors. After the Rana Plaza tragedy, developments have been made in the apparel industry. But other industries are not focused properly.

Significant Labour Laws in Bangladesh

Bangladesh Labour Act 2006

Bangladesh Labour Rules 2015

Bangladesh National Building Code 2006

National Occupational Safety and Health Policy 2013

Domestic Workers Protection and Welfare Policy 2015

The Government of Bangladesh has developed the National Occupational Safety and Health Policy, 2013 and the Domestic Workers Protection and Welfare Policy 2015 to advance health, safety and dignity for the workers. Apart from these, three laws serve as a manual to ensure workers safety and overall well-being. These are Bangladesh Labour Act, 2006 (BLA), Bangladesh National Building Code, 2006 (BNBC), and Bangladesh Labour Rules, 2015 (BLR).

Restrictions on Use of Defective Machinery

The chapter 6 of BLA focuses on restricting the use of defective machinery and mandates their regular monitoring and maintenance .

Extra Fees and Safety for Dangerous Machinery

Rule 57 of the BLR makes the payment of extra fees and availability of sufficient safety kits mandatory to the employers if dangerous machinery is used.

Proper Training for Using Machinery

Along with fulfilling these criteria, employers also need to provide proper training, according to section 78A of BLA.

Eye Protection Goggles

Furthermore, section 75 and rule 64 shed light on the need for eye goggles to prevent eye-related hazards and measures to tackle harmful smoke, respectively.

Sufficient Medical Aid and Ingredients

To provide a swift treatment and reduce the risk of injuries, section 89 of the BLA makes it mandatory that every workplace must have sufficient basic medical aid for its workers. Rule 76 precisely mentions the ingredients necessary to be present in such medical aid kits.

Prohibition of Child Labour

Section 34 of BLA imposes prohibition on child labour except in special circumstances.

Maximum Working Hour

Furthermore, Section 100 specifies the maximum working hour by 8 to 10 hours except special circumstances.

Weight Lifting Limitation

Section 74 mentions that workers cannot be made to lift excessively heavy objects.

Safety of Women

According to Section 109 of the Labour Act, a woman being made to work at night without her consent is unlawful. On the other hand, Section 332 stipulates that “No one in the workplace shall behave with a woman in a way, which may seem to be indecent or unmannerly or which is repugnant to the modesty or honour of that woman.”

Subsequent Changes after the Rana Plaza Tragedy

On April 24, 2013, the collapse of the Rana Plaza building in Dhaka led to at least 1,132 fatalities and more than 2,500 injuries. This accident served as a wake-up call and indicated the poor working condition of the RMG sector in Bangladesh. As a result, the Government of Bangladesh took several steps to bring a change in the laws and provisions regarding work safety. After the Rana Plaza incident, the garment industry went through a massive structural transformation.

In 2020, a Sustainability Council was developed in order to ensure building and fire safety. Many buildings have undergone structural, electrical, and fire assessments to ensure their compliance with the National Fire Code and the Bangladesh National Building Code (BNBC).

0

Risky Factories Closed after Inspection

Safety committees have also been formed to regulate and control the safety progress regarding structural defects, blocked emergency exits, unsuitable fire alarms, and fire spray systems in different sectors of the apparel industry. Around 84% and 90% of these issues at the Accord factories and the Alliance factories have been resolved and addressed respectively. Within five years of the Rana Plaza accident, the Accord fired 96 of its 800 dealers and the Alliance 168 of its 2,000 suppliers. Furthermore, training has been provided to several employees and a central fund has been formed by contributing $10 million of export receipts for workers’ welfare purposes. The government of Bangladesh inspected 1,549 factories and closed 513 risky factories as well.

The Labor Law was amended in 2013 and 2018 by integrating and modifying the sections 78(A), 80, 82, 89, 90(A) and 90 to comply with the OSH.

Moreover, the minimum monthly wage of the garment workers was fixed at 8,000 taka in 2018, which was 3,000 taka in 2010. The RMG sector had no proper trade unions. But now around 1,100 registered trade unions are there to ensure workers safety.

Actions Undertaken to Facilitate Changes

Formation of the Alliance for Bangladesh Worker Safety

In 2013, the government brought an amendment in its labour law to enhance workplace safety. The amendment made a safety committee of 6-12 members mandatory for factories with at least fifty workers to ensure the labour well-being.

1.2 Million Workers

Safeguarded by Alliance

6-12 Members

Mandatory safety committee for each factory

In the same year, a group of 29 US-based multinational retailers formed the Alliance for Bangladesh Worker Safety, covering 600-700 garment factories and 1.21 million workers in Bangladesh. The alliance ensured the workplace safety measures like building safety audits and worker training programs for the member companies. The Alliance also contributed in developing a key part of the Government’s 2013 action plan to improve safety conditions.

But the enforcement of workplace safety regulations was not completely successful in factories. By the middle of 2017, only 210 of these 1,549 factories had formed safety committees.

The Alliance’s safety committee enforcement program highlighted the availability of safety committees in domestic factories. The program tried to incorporate committees to factories and ensured the seamless running of existing committees. The Alliance trained committee members and monitored committees’ performance as well. The timeline of the enforcement program was 2.5 months, followed by a six month program to monitor the committee activities.

Though, this program could help in increasing the workers safety to some extent, the long term impact was not that much visible. Furthermore, it increased the workers dissatisfaction as a result of more expectations from the program.

ADB Loan for a Safer Workplace

In August 2015, with an aim to foster health, safety, labour standard and construct effluent water treatment plants in RMG sectors, ADB approved a loan of up to $30 million to the BRAC Bank. This loan has so far worked to develop three RMG companies in Bangladesh-Energypac Fashion Limited (Energypac), Graphics Textiles Limited (Graphics), and Raquef Washing and Packaging Industries Limited (Raquef).

Separate Female Washroom | Daycare Center | Canteen

Provided in 3 Companies

Increase in Exports of Energypac

From US$ 18m to US$ 75m in 5 years

A gender action plan (GAP) was embraced as part of the project due to the large presence of women in the garments sector. With this loan, factories built separate restroom facilities for male and female workers, daycare centres for working mothers, canteen and healthcare facilities. Safety training and monitoring was provided as well. This project overall developed the working environment for labourers and more significantly, for women workers.

Due to the partnership with the BRAC Bank through this ADB loan, Energypac has been able to expand its production area from 64,500 to 215,000 square feet, and has increased its exports from US$18 million in 2017 to US$ 75 million in 2022. They have also earned the platinum certification in the Leadership in Energy and Environmental Design rating system in recent times.

Campaigns Regarding Workplace Safety

ILO launched a campaign on 30 March, 2017 to raise awareness of basic Occupational Safety and Health issues and their prevention in the RMG sector of Bangladesh.

The radio-based campaign entitled, ‘Safe Workplaces, Go ahead Bangladesh’ was implemented in the collaboration of the Ministry of Labour and Employment, the Department of Inspections for Factories and Establishments (DIFE) and the ILO with funding from Canada, the Netherlands and the United Kingdom. This campaign reached out to garment workers to make them aware of workplace safety issues.

A series of 19 radio episodes was broadcast on Dhaka FM 90.4. Each 30-minute radio episode focused on a particular OSH related issue including emergency measures, dramas and discussions. The face of this campaign was television celebrity Mr. Mosharraf Karim.

Sustainable Action for Promoting Safety Project

In January, 2019, a project titled ‘Sustainable action for Promoting Safety‘ for RMG Industries was taken up to develop a compelling legal strategy with an aim to develop workers safety. The project was funded by Manusher Jonno Foundation and the duration was three years. The project is located at Mohammadpur, Savar, Mirpur and Gazipur Sadar. The direct beneficiaries of this project are 4400 female workers along with 1080 male workers.

SAPS assessed partner factories’ needs and demands through baseline surveys, workshops and conferences. Moreover, periodic monitoring, development and risk assessment helped in the effective functioning of factory based structures. This project also launched an app to ensure proper wage calculation for workers. Inclusion of the POSH committee and the facility to consult with the stakeholders make the project more fruitful.

Development of National Action Plan

In October 2019, the Government agreed to develop a National Action Plan (NAP) on the Labour Sector of Bangladesh in the 9th session of the EU-Bangladesh Joint Economic Commission. The timeline of this action plan is 2021 to 2026. The NAP was developed along with the European Union (EU) and the draft was shared on 1 July 2021.

Legal and Administrative Reforms

Enforcement of laws, capacity building and promotion

Bringing Labour Laws in Compliance with ILO Standards

Freedom of association, collective bargaining, eliminating child labour etc.

The NAP aims to ensure labour rights and workplace safety in the country. The plan consists of specific actions on legal and administrative reforms as well as enforcement of laws, capacity building and promotional activities.

The Ministry of Labour and Employment (MOLE) has formed a Tripartite Implementation and Monitoring Committee (TIMC) to monitor the timely progress of implementation of the National Action Plan (NAP). The 7th meeting of TIMC was held on 11 September, 2023. The NAP will work to achieve certain goals. These goals include bringing Bangladesh labour laws in compliance with ILO standards on freedom of association and collective bargaining, eliminating child labour in all its forms by 2025, combating violence against workers, harassment, unfair labour practices and anti-union discrimination etc.

Vulnerable Supply Chain Facility Project

Along with Marks and Spencer, CARE took up the “Vulnerable Supply Chain Facility“ project. This project aims to provide a better health service for 80,000 factory workers, of 25 factories from selective areas of Gazipur, Savar and Valuka. The duration of this project was August 1, 2020 to July 31, 2021. UK Aid and Mott MacDonald Limited funded this project.

The training was provided on maintaining personal hygiene, the importance of frequent hand wash, nutritious food intake, and maintaining menstrual hygiene. Moreover, awareness about COVID-19 such as maintaining physical distance, wearing masks, COVID-19 vaccine intake and registration related training were also provided under this project.

Adaptation of the OSH Profile

In November, 2021, the draft of the Occupational Safety and Health (OSH) Profile was made by the Department of Inspection for Factories and Establishments (DIFE), along with the Ministry of Labour and Employment, social partners and other relevant stakeholders.

The ILO’s Improving Working Conditions in the Ready-made Garment programme provided technical support in the materialisation of this policy instrument. The OSH Profile aims to mitigate work environment hazards. Moreover, an OSH Profile is necessary to monitor and evaluate the national situation on workplace accidents and diseases. It helps to understand the progress over time as well.

The OSH Profile presents detailed information on OSH-related laws and regulatory frameworks and relevant data on inspections, complaints, safety committees, occupational accidents and compensation for accidents. Thus, this document is mandatory for the policy makers to take practical and situation based decisions.

Establishment of the Employment Injury Scheme

In June, 2022, Bangladesh established the Employment Injury Scheme to ensure income protection and medical care for work-related injuries.

A tripartite committee oversees the task of piloting the EIS. The committee is comprised of representatives of the Ministry of Labour and Employment, Bangladesh Employers’ Federation (BEF), Bangladesh Garment Manufacturers and Exporters Organisation (BGMEA) and Bangladesh Knitwear Manufacturers and Exporters (BKMEA), National Coordination Committee for Workers’ Education (NCCWE) and Jatiya Sramik League (JSL).

The International Labour Organization and the Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) supported in turning the pilot design into reality.

There are two components of this pilot scheme.

Based on sample factories, research will be conducted on the average medical costs for a worker in case of injury to meet the resources necessary for the medical care. Around 150 factories participated to generate the evidence needed for a long-term solution.

In compliance with the requirements of ILO Employment Injury Protection Convention, 1964 (No. 121), the EIS will compensate all the injured RMG workers and their dependents (in case of accidents that cause permanent disability and death). This compensation will be in the form of periodical payments as top-ups for the already existing lump-sum payments of the Central Fund. These top-up payments will be provided by voluntary contributions of international brands and retailers.

Increasing the Capacity of DIFE

In August, 2022, the government came forward to bolster the capacity of the Department of Inspection for Factories and Establishments, in order to ensure workplace safety. This step has been taken in alignment with the commitment provided to the government’s development partners, including the European Union and International Labour Organization (ILO).

0

Industrial Inspectors Appointed

To strengthen the capacity, the labour ministry approved around 162 new posts for the department and created a total of 30 additional posts of labour inspectors. The department had 888 posts then, among which there were only 311 inspectors against the post of 575 inspectors. Of the remaining 264 posts, 140 will be appointed by direct recruitment, 112 will be filled up through promotion and the rest 12 will be reserved.

Initiatives are also taken to set up eight new inspectorate offices in Gopalganj, Manikganj, Feni, Brahmanbaria, Cox’s Bazar, Rangamati, Jamalpur and Naogaon.

Recommendations

- The government should come forward to relocate around 1200 factories situated in debilitated residential areas and multi-story buildings in Old Dhaka. Moreover, the DIFE can establish an ISU-plastic unit according to the national and international safety protocol to maintain safety outside old Dhaka.

- Development partners should diversify their investments to include the other sectors, rather than focusing solely on the RMG sector.

- All organizations should form effective complaint committees regarding sexual harassment-related complaints. In order to ensure a women friendly workplace, regular training regarding gender equality and rights is also necessary.

- Multiple ministries and government agencies are overseeing occupational safety and health in the industrial sector. But the lack of a unified policy and overlapping of responsibilities have hindered the progress. Thus, coordination among the relevant authorities is necessary.

- Permitting more trade unions can effectively ensure safety in workplaces. Effective collaboration between ILO and National Coordination Committee for Worker Education (NCCWE) along with IndustriALL Bangladesh Council (IBC) can help in this regard.

About the Author

Umme Farzana Rupa, a former debater, currently excelling as a passionate student at Bangladesh University of Professionals. Engaging communicator and dedicated learner, she continues to thrive in academics, leaving her mark on campus with her inquisitive spirit and determination.