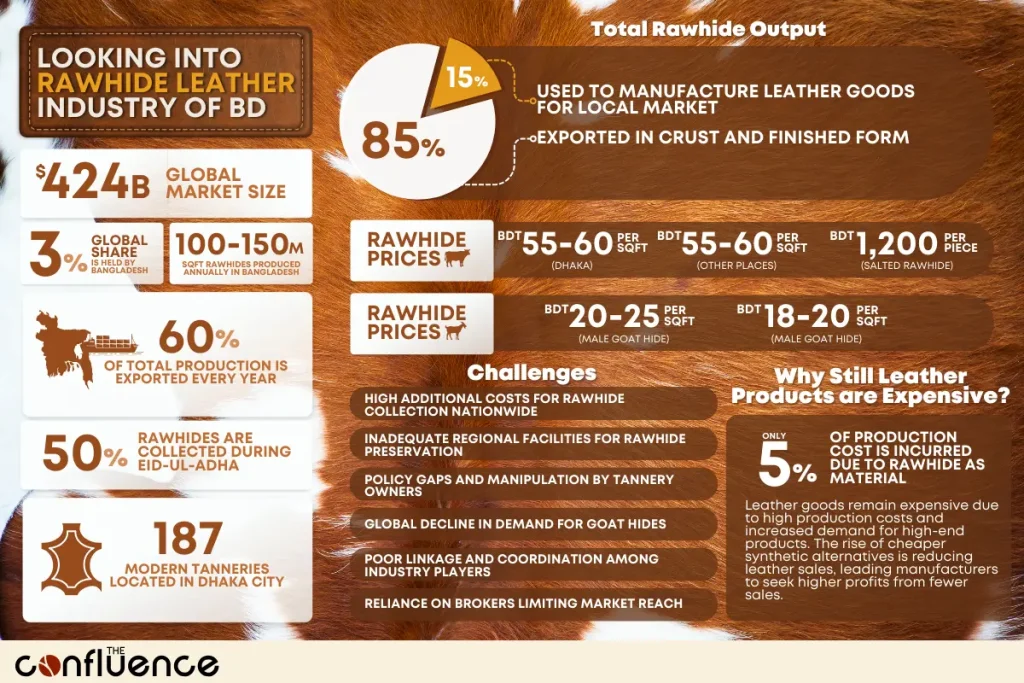

Bangladesh holds a 3% share in the global leather and products market, with nearly 60% of its yearly production being exported. The country has seen a significant increase in leather and leather product exports over recent decades. Dhaka city alone houses approximately 187 modern tanneries.

Status Quo of Leather Industry of Bangladesh

0

%

Share in the global leather and products market

60% Leather Exported

Of the total production

187 Modern Tanneries

In Dhaka City

Status Quo of Raw hide Industry of Bangladesh

0

M

Sq. ft raw hides and skins produced annually

80% Raw Hide Exported

Of the total production

50% Raw Hide Collected during Eid

Eid-ul-Adha

Bangladesh produces around 100-150 million square feet of raw hides and skins annually, with about 85% of this output exported in crust and finished forms. The remaining hides and skins are used to manufacture leather goods for the local market. According to the BTTC data, more than 50 per cent of raw hides and skins are collected during the Eid-ul-Adha.

Government-Set Price of Rawhides

Ahead of Eid-ul-Adha, the prices for salt-applied rawhides of cows have been fixed at BDT 55-60 per square foot in Dhaka and BDT 50-55 per square foot in other places of the country this year. In Dhaka, salted cow rawhide is priced at BDT 1,200 per piece, and outside Dhaka, it is BDT 1,000 per piece. Meanwhile, goat hide is priced BDT 20-25 per square foot nationwide, with female goat hide priced at BDT 18-20 per square foot.

Government-set Price of Raw Hides (Upper Limit)

Per Square Foot

No Data Found

Last year, the prices for salt-applied rawhides of cows were BDT 50-55 per square foot in Dhaka and BDT 45-48 per square foot across the country. During the first two days of Eid-ul-Adha last year, over 0.45 million pieces of rawhides were collected.

Similarly, last year’s goat hide prices were BDT 18-20 per square foot nationwide, and female goat hide was BDT 12-14 per square foot across the country.

The Process of Leather Production

Cattle hides and skins serve as a significant raw material for leather, a by-product of the meat industry. Leather is the primary product of tanneries and undergoes further processing by industries such as footwear, clothing, furniture, and car manufacturing. In Bangladesh, black goatskin from Kushtia is renowned for its fine grain and flexibility, attributed to the humane treatment of domestic animals.

Tanning refers to the process of converting raw animal hides and skins, primarily from cattle, into leather. Historically, small to medium-sized family businesses dominated the tanning industry. However, with increasing demand for leather and leather products, tanning processes have evolved, and larger companies now play a prominent role.

The tanning process involves trimming the hides and skins upon arrival at the tannery to remove unwanted elements. Subsequent operations include soaking, liming, fleshing, de-liming, bating, degreasing, and pickling to prepare the hides for tanning. Wet blue leathers are processed into crust leathers, which serve as raw material for producing finished leather in the final stages of manufacturing.

Challenges in Maintaining Government-Set Rawhide Prices

Selling rawhides at government-set prices in Bangladesh has become difficult for traders due to several reasons. Despite efforts to regulate prices, traders face significant challenges that make it hard to comply with fixed rates.

Additional Costs Involved

One major hurdle is the additional costs involved in collecting rawhides nationwide. Besides the fixed government price, traders must cover expenses like salt for preservation, technical costs, transportation, labour, and other miscellaneous charges. These extra costs, according to estimates from the Bangladesh Hide and Skin Merchants Association (BHSMA), substantially raise the overall procurement expenses, making it economically impractical to sell at the fixed price.

Inadequate Preservation Facilities and Backward Linkage

0

%

Of collected raw hides damaged by rainfall

Moreover, inadequate preservation facilities at regional levels result in a significant portion of collected rawhides either rotting or being sold at very low prices. Last year’s heavy rainfall during Eid worsened the situation, damaging about 10% of the total collected volume due to poor preservation and weather conditions.

Policy Gap and Collusive Activities

Policy gaps, tanner syndicates, and manipulation by Dhaka tannery owners are also to be blamed for the drastic drop in rawhide prices. Field-level rawhide traders are not included in the Ministry of Commerce meetings where rawhide prices are fixed, leading to an unfair situation for traders. This lack of representation and transparency complicates matters further.

Additionally, there are indications that syndicates may be influencing the acceptance of government-fixed rates, adding to the complexity of the situation.

Global Decline in Goat Hide Demand

Furthermore, the global decline in demand for goat hides and the closure of local tanneries that process these hides have significantly impacted prices, making it challenging for traders to adhere to government-fixed rates. Tannery owners attribute their reduced purchases of goat hides to this decreased demand.

Lack of Backward Linkage

The leather and tannery industries in Bangladesh suffer from underdeveloped backward linkage and inadequate supply chain, leading to frequent shortages of raw hides and skins. Manufacturers often rely on imported machinery and chemicals for production.

Additionally, most tanners and commercial leather exporters depend on brokers to connect them with buyers. This reliance on intermediaries limits processors’ ability to expand their reach within the supply chain. Compounding the issue is the dominance of a few local companies that subcontract to Micro, Small, and Medium Enterprises (MSMEs), highlighting poor linkage and coordination between smaller enterprises and industry leaders.

Furthermore, there is a lack of market information and promotion, coupled with insufficient marketing knowledge among local leather entrepreneurs. These factors collectively hinder the industry’s growth and competitiveness.

Price of Rawhide vs Complete Leather Goods

Cheap rawhide prices do not mean that leather goods like footwear, belts, and bags will be very inexpensive. Rawhide only accounts for 5% of the production cost. The remaining 95% of the cost is associated with accessories such as labour, transportation, branding, administrative and managerial work, running establishments, bank interest rates, and stock lots.

Globally, the demand for high-end and semi high-end leather goods has increased. Consequently, local leather footwear and leather goods manufacturers in Bangladesh have recently focused on making such products, leading to higher prices and enhanced comfort.

Most leather footwear manufacturers previously used wood for soles, but now they use natural rubber, which is more expensive. In the international market, the use of synthetic or nylon thread-made non-leather footwear and other products is growing significantly. Many people now prefer non-leather shoes for office wear because they like casual attire. Additionally, synthetic products are cheaper, attracting a large consumer base.

As a result, leather shoes and products are being pushed out of the market, negatively impacting sales. This has led leather goods manufacturers, especially in the shoe segment, to seek larger profits from a smaller quantity of shoes sold to fewer customers. This situation drives manufacturers to try to keep rawhide prices as low as possible.

Factors Contributing to Rejection in Foreign Market

Poor Animal Husbandry

Reasons for Defective Raw Hides in Bangladesh

In Percentage (Upper Limit)

No Data Found

Bangladeshi rawhide often faces rejection in foreign markets due to various quality issues and defects. Pre-mortem defects like hair slip (7%), parasitic infestations (5%), wounds (2%), and pox marks (3%) occur before the animals are slaughtered, indicating poor animal husbandry and livestock handling.

Poor Leather Processing

Post-mortem defects arise during leather processing, including flay cuts (21-23%), pox marks (9-19%), parasites (3-9%), growth marks (19%), wounds (11%), burns (4%), scratches (2-7%), and moles (2%). These result from improper flaying techniques, inadequate hide preservation, and substandard tanning processes.

Mechanical faults during leather processing, although minor (1-2%), also contribute to defects and the rejection of Bangladeshi rawhide in foreign markets.

Unavailability of High-quality hides

- Premium-Grade15 %

- E,F Grades35 %

- G,H Grades35 %

- HH Grade25 %

Additionally, the availability of high-quality hides and skins in Bangladesh is declining, making it difficult to produce premium-grade leather that meets international standards. Only 10-15% of leather produced in Bangladesh achieves the highest quality grades, while a large portion falls into lower grades, such as E, F (30-35%), G, H (30-35%), and HH (20-25%), reducing its acceptability in foreign markets.

Lack of Consistent Quality Control Measures

Another critical issue is the lack of consistent quality control measures and adherence to international standards throughout the leather production process in Bangladesh. This results in up to 70% of lower-grade leather, causing significant economic losses for the industry.

Steps Taken to Resolve the Issues

Relocation of Tannery Factories

In 2001, Bangladesh’s High Court ordered the relocation of tannery factories. The plan for the Savar Tannery Estate was approved in 2002. The government signed the first Memorandum of Understanding (MOU) with the Bangladesh Tanneries Association (BTA), the Bangladesh Finished Leather and Leather Footwear Exporters Association (BFLLFEA) in 2003 to facilitate this move. However, the Tannery Estate Dhaka (TED) did not start operations until April 2017.

Prevention of Smuggling

The country’s largest rawhide market outside Dhaka is located at Rajarhat in Jessore. Traders are concerned about the raw hides being smuggled to India due to the activities of a syndicate that appears to be actively buying them. To combat this, the Jessore district administration has taken measures to prevent the smuggling of raw hides through Benapole to India since 2013.

Police and Border Guard Bangladesh (BGB) are on high alert in these areas to prevent smuggling. Checkpoints have been established, and the transportation of vehicles carrying raw hides towards the borders has been banned.

Despite the government providing millions of taka in loans to tannery owners, rawhide businesses do not receive similar support. When tannery owners lower the prices of raw hides, traders are tempted to smuggle them for higher profits. Smugglers purchase raw hides from local neighbourhoods at prices higher than the market rate and then pass them for smuggling.

The Bangladesh Leather and Leather Goods Development Policy

In 2019, the Bangladesh government introduced the Bangladesh Leather and Leather Goods Development Policy to boost the leather and leather goods industry. This policy significantly impacted the rawhide sector, a key material for the industry.

A main goal of the policy was to ensure quality rawhide was available at fair prices. To achieve this, the policy included several measures:

Establishing Rawhide Collection Centres

The policy encouraged setting up collection centres, especially in livestock-heavy areas, to streamline collection and ensure proper handling and storage.

Promoting Modern Slaughterhouses

The policy called for the construction of new, hygienic slaughterhouses and the upgrading of existing ones to meet international standards, improving rawhide quality.

Improving Transportation and Logistics

The policy highlighted the need for efficient transportation and proposed improvements in infrastructure and the use of refrigerated vehicles to maintain rawhide quality during transit.

Providing Training and Awareness Programs

The policy aimed to train butchers, intermediaries, and traders on proper handling techniques, preservation methods, and quality maintenance through awareness programs.

These measures positively affected the rawhide sector. Collection centres streamlined the supply chain and reduced waste. Modern slaughterhouses improved rawhide quality through better hygiene and techniques.

Permission to Export Rawhide

In 2020, just before Eid-ul-Adha, the Bangladesh government decided to allow rawhide exports temporarily for the first time in the country’s history. Rawhide merchants must obtain permission from the commerce ministry before exporting rawhide. The government would evaluate the price of sacrificial animal rawhide, the demand from tanners, and the supply to tanneries before granting approval.

0

M

Sq. ft wet blue hides permitted to be exported

5 Companies Allowed to Export

ASK Investment, Kader Leather Complex Ltd, Amin Tannery Ltd, Leather Industries of Bangladesh Ltd. (Unit 2) and Kalam Brothers

2 Million Sq.ft.

Export by each company

There is no minimum export price condition. Previously, the country exported wet blue leather, semi-processed, chrome-tanned leather, until 1989 when the government banned it to support the growing footwear and leather goods industry.

In 2021, the government permitted five companies to export ten million square feet of wet blue hide. The approved quantity was instructed to be exported to the European Union, Russia, Ukraine, China, Hong Kong, Korea, Vietnam, and Japan by June 30, 2022. The companies, ASK Investment, Kader Leather Complex Ltd, Amin Tannery Ltd, Leather Industries of Bangladesh Ltd (unit-2), and Kalam Brothers, each received approval to export 200,000 square feet of rawhide.

Initiative to Preserve Rawhides

In 2021, the Ministry of Industries initiated a plan to preserve sacrificial animal rawhide in dochala houses by using adequate salt, ensuring fair prices for rawhide at the grassroots level. The ministry has provided guidelines for implementing this initiative through the district administration. With this method, rawhide can be stored for up to three months, and if tannery owners purchase leather from these locations, the quality will remain intact.

Additionally, the Ministry of Industries has taken steps to ensure a steady supply of salt to dealers, wholesalers, and retailers for the proper preservation and processing of sacrificial animal rawhide during Eid-ul-Adha. The government has also launched campaigns, publicity efforts, and distributed leaflets to educate the public on the correct collection and preservation of rawhide.

Establishment of Effluent Treatment Plants

Despite the demand in domestic and international markets, rawhide prices have been low in recent years. The government has recently taken steps to establish Effluent Treatment Plants (ETPs) in leather industrial cities to resolve this issue. However, the work on the central Effluent Treatment Plant (CETP) of the tannery estate remains incomplete.

Planned Measures

Government authorities have prepared a plan to ensure fair practices in the rawhide trade, which is crucial for Bangladesh’s export-oriented leather industry, as around 13 million animals are expected to be sacrificed during Eid-ul-Adha. The Ministry of Commerce (MoC) met with stakeholders in May 2024 to outline steps to prevent price manipulation, and to ensure the proper collection, preservation, and management of rawhide and skins from sacrificial animals.

The ministry has instructed relevant state agencies to implement these measures by forming monitoring teams and establishing a control cell to oversee buying, selling, preservation, and transportation of rawhide. Additionally, the Ministry of Home Affairs is working on facilitating the transport of hides across the country and increasing border vigilance to prevent smuggling. The police, BGB, and an intelligence agency have been asked to ensure that there are no obstacles during rawhide transportation and to enforce a ban on transporting sacrificial rawhide seven days after Eid. They will also increase monitoring at key points, including border areas.

Representatives from various state agencies, including the ministries of home, fisheries and livestock, industries and religious affairs, and the cabinet division, as well as traders and their associations, attended the meeting to prepare for Eid-ul-Adha. The MoC has also directed the agencies to monitor salt prices to prevent overpricing.

Recommendations

- Sustainable infrastructure should be developed by creating a specialised leather industry zone that complies with environmental rules and regulations. Although costly, owners must maintain ETPs in every tannery as a mandatory requirement. Effective Environmental Management Plans are essential.

- The government should monitor industries by ensuring adequate power and utilities. It should also develop sustainable and profitable partnerships between buyers and sellers through effective political and commercial negotiations.

- The government should establish modern rawhide preservation facilities across major livestock hubs to prevent rawhides from rotting or being sold at low prices. This includes creating refrigerated storage units for immediate chilling and preservation, promoting industrial-grade salt curing facilities to prevent bacterial growth, and providing training programs for traders and butchers on modern preservation techniques.

- To improve acceptance in foreign markets, the government should enforce quality standards and implement a traceability system. This includes developing a digital system to track rawhide from collection to tannery delivery, establishing grading standards and a certification process based on international parameters, and conducting regular inspections of slaughterhouses and warehouses to ensure adherence to hygiene and handling protocols.

- The government should offer incentives, such as subsidies and tax rebates, to traders and suppliers who consistently provide high-grade, export-quality rawhides that meet established standards. This encourages adherence to quality control measures and supports the production of superior rawhide products.

About the Author

Umme Farzana Rupa, a former debater, currently excelling as a passionate student at Bangladesh University of Professionals. Engaging communicator and dedicated learner, she continues to thrive in academics, leaving her mark on campus with her inquisitive spirit and determination.

1 comment

[…] Bangladeshi government has recognized the leather industry as one of the thrust sectors where footwear has a significant role. The leather industry generates […]