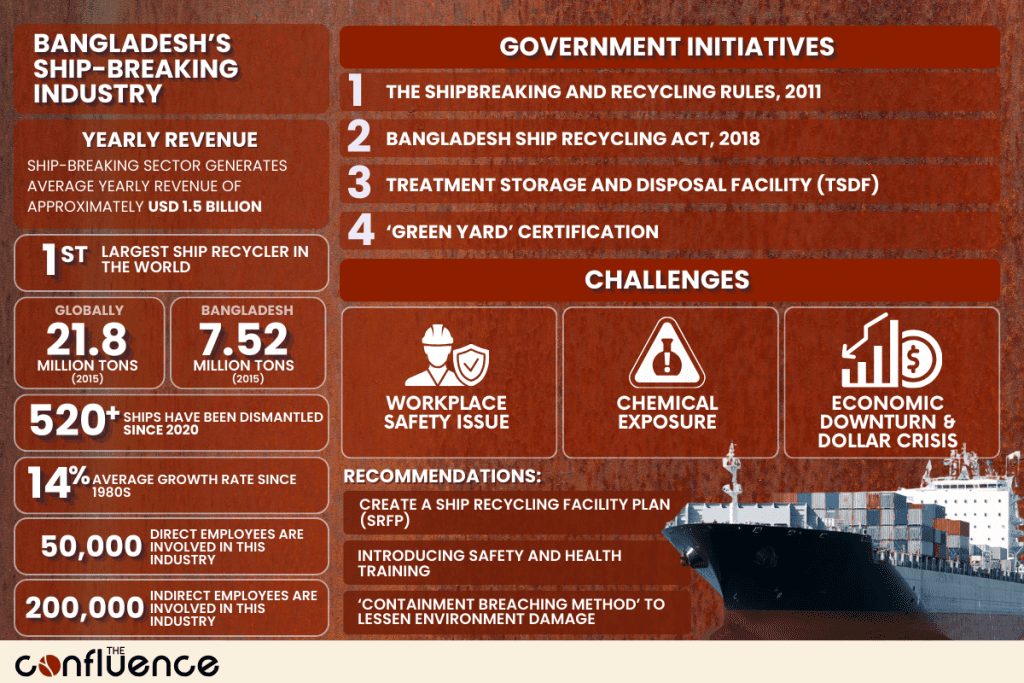

Once a prosperous industry with significant health hazard for its cheap labour, Bangladesh ship breaking industry has come under scrutiny and regulations. Despite higher regulations, the industry was thriving pre-COVID. How has the pandemic affected this large scale industry?

Bangladesh produces around 6 million tons of steel rods annually, with 80–90% of the raw materials used in the manufacturing process coming from the shipbreaking industry. The shipbreaking sector has continued to prosper as a result of the nation’s growing need for steel to sustain its development, and this prosperity is now seen as advantageous to the country’s economy.

0

T

Steel produced in Bangladesh annually

80-90% Raw Materials

Provided by ship breaking

47.2% of Global Tonnage

Scrapped by Bangladesh

Bangladesh’s coastline position makes it a rising star in the global shipbreaking sector. Because it supplies raw materials to the steel, shipbuilding, and other sectors in Bangladesh and some other South Asian countries, the shipbreaking business in Bangladesh has grown significantly over the past 20 years. Bangladesh has continued to be the country with the most amount of shipbreaking over the last six years. In 2018, Bangladesh transcended the shipbreaking industry with 47.2% of the Global tonnage (UNCTAD, 2019).

$

0

B

Average annual revenue of ship breaking industry

30% of the World’s Light Displacement Tonnage

Scrapped in Bangladesh between 2000 and 2010

Bangladesh’s ship breaking business (SBI) benefits from low labour costs, a flat homogeneous intertidal zone, modest law enforcement, and local demand for steel and iron. Numerous sources state that Bangladesh’s shipbreaking sector generates average yearly revenue of approximately 1.5 billion dollars. About 30% of the world’s Light Displacement Tonnage (LDT) is estimated to have been scrapped in Bangladesh between 2000 and 2010. It is now a significant and lucrative industry for the country.

0

%

Average growth rate of ship breaking since 1980

21.8 Million Gross Ton

Ship recycled worldwide in 2015

7.52 Million Gross Ton (34.5%)

Ship recycled in Bangladesh in 2015

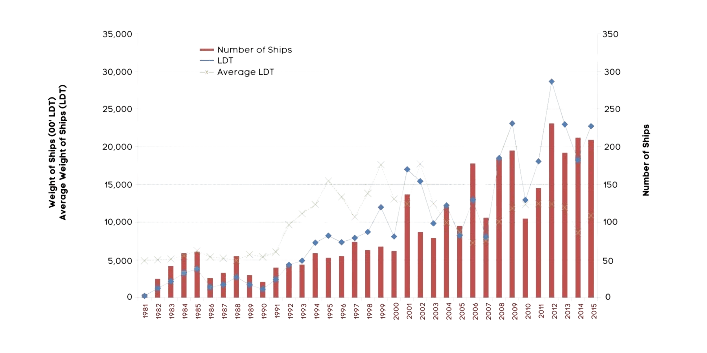

Global ship recycling in 2015 reached a total of 21.80 million Gross Tons (GT), with Bangladesh being the largest recycler with 7.52 million GT (34.5%). (2015 Global Casualty Statistics). Research indicates that since the 1980s, the industry has grown at an average rate of 14%.

0

Ships dismantled in Bangladesh since 2020

22,000 – 50,000 Direct Employment

In Bangladesh’s ship breaking industry

100,000 – 200,000 Indirect Employment

In Bangladesh’s ship breaking industry

According to research by the World Bank and the NGO Young Power in Social Action, there are 22,000 to 50,000 direct employees at shipbreaking yards in Bangladesh and 100,000 to 200,000 employees are involved indirectly. Over 20,000 Bangladeshi labourers have dismantled over 520 ships since 2020—much more tonnage than any other nation.

Currently, Bangladesh’s ship breaking sector is supporting a wide range of heavy and light engineering industries. Furthermore, this sector is providing thousands of people in the nation’s poorest districts with employment opportunities.

“The development of Bangladesh’s Ship Recycling Industry over the last 14 years is amazing. Upon my return, I intend to advocate for our ship owners to consider Bangladesh as a viable option,” after paying a visit to the Kabir Steel Ship Recycling Facilities in Chattogram’s Sitakunda upazila in March 2024. He also added “A decade ago, in 2010, I found the ship recycling industry here to be a hazardous and disorganised mess. This visit, however, reveals a remarkable transformation. This industry has become a world leader in ship recycling with its focus on safety and aesthetics.”

Erik Solheim

Former Climate and Environment Minister of Norway

The Trajectory of the Shipbreaking Industry in Bangladesh

1960-1999

Prior to the 1960s, shipbreaking was considered a highly mechanized industry originating predominantly in the United States, the United Kingdom, Germany, and Italy. In an attempt to maximize profits, ship owners in the early 1980s started sending their vessels to scrap yards in China, India, Pakistan, Bangladesh, the Philippines, and Vietnam, where workers are in severe need of work and circumstances for pay, health, and safety are appalling. A natural tragedy served as the impetus for the shipbreaking industry’s establishment in Bangladesh rather than careful preparation and execution.

1964

Capsized Greek ship “MD Alpine” scrapped

1974

Salvaged Pakistani Navy vessel scrapped

A tidal surge in the Bay of Bengal caused the Greek ship “MD Alpine” to capsize in 1960 during a cyclone off the coast of Faujdarhat in Sitakunda Upazila. After purchasing the ship in 1964, Chittagong Steel House began dismantling it for scrap metal. In 1974, ten years after it had been sunk during the Bangladesh independence war, a salvaged Pakistani navy vessel was destroyed by Karnafully Metal Works. The shipbreaking industry in Bangladesh began with these two instances.

The hub of shipbreaking activity in Bangladesh is Sitakund (Bhatiary to Kumira), which is situated on the Bay of Bengal, precisely to the north of Chittagong. The coast of Bangladesh provides a wide range of tides, an ideal intertidal zone for large vessel beaching, moderately cheap labor, and flexible environmental constraints, according to Hossain et al. (2008). Due to the availability of inexpensive labor and the consequent increase in demand for iron, the shipbreaking industry began slowly.

By the middle of the 1980s, Bangladesh had become one of the world’s top ship-breaking countries. But the investment momentum started to pick up steam in the 1990s. Businesses in Chattogram and Dhaka realized they could earn from each ship twice or three times over their initial investment, which offered them a significant potential. Due to its high population density and standing as a developing country in the third world, it had access to a large labor pool at lower wages. The shipbreaking business grew relentlessly, driven by the nation’s increasing need for steel to progress. Consequently, this economic sector has been consistently recognized as advantageous.

2000-2019

0

Scrap ships imported between FY 01-02 and FY 20-21

37.6 Million Tons

Scraps processed between FY 01-02 and FY 20-21

51% Raw Materials | 37% Finished Steel Products

Output of ship breaking industry

23% of Total Rolling Industry Production

Ship breaking accounted for

SBI inflows have been increasing, and tonnage dismantled reached a record high of 2,308,525 LDT (light displacement tonnage) after 2009. From FY2001-02 to FY 2020-21, Chattogram shipyards imported a whopping 3,329 scrap ships. These ships contributed to more than 37.6 million tons of scrap being processed in Bangladesh. In 2012, shipbreaking industries (SBI) supplied approximately 51% of raw materials and 37% of finished steel products. In FY2010, the rolling industry produced 1,451,000 tons, with shipbreaking accounting for 23% of the total. SBI was found to be the sole source of scraps for small rerolling factories in Bangladesh, and their output after 2008 more than doubled compared to 2005.

In the shipbreaking industry, several accidents and fatalities occurred, however not many of them were reported. In 2010, the legal dispute between the environmentalist group and the shipbreaking association resulted in a brief halt of all shipbreaking activities. In addition, on May 17, 2009, the High Court of Bangladesh issued a ruling that forbade shipbreaking yards from importing ships unless they first obtained an “Environmental Clearance Certificate” from the Department of Environment. All shipbreaking yards in Chattogram were ordered to be closed in 2009 by the Supreme Court of Bangladesh since none of them had the required environmental permits to be in operation. The yards reopened with only partial authorizations and unaltered procedures after a mere two months of shutdown. But after 2010, a lot of these shipyards started to close because they could no longer compete in the global market, and bank loan interest rates were going up.

- 20142605099 Tons

- 20152488844 Tons

- 20163405068 Tons

- 20172128763 Tons

- 20182540178 Tons

- 20192360714 Tons

- 20202039666 Tons

The Bangladesh Ship Breakers and Recyclers Association reports that 227 ships totaling 2,605,099 tons were imported in 2014. Imports peaked in 2016 at 3,405,068 tons, despite a modest decline to 2,488,844 tons the previous year. The following four years’ import numbers were 2,128,763 tons, 2,540,178 tons, 2,360,714 tons, and 2,039,666 tons, respectively, from 2017 to 2020.

2020-2024

In 2020, Bangladesh dismantled about one-third of the world’s total tonnage. Approximately 7 million tons of the 15.8 million tons of metal produced globally from dismantling ships, occurred just in Bangladesh. Consequently, the nation experienced a reduction in its foreign reserve depletion due to the relatively diminished requirement for steel imports. In a similar vein, the government benefited greatly from the variety of activities within this industry. Shipbreaking yards not only collect steel scrap but also a variety of other products that can be salvaged, recycled, or sold at the yard gate or local market, such as furniture, appliances, sheets, nets, bar supplies, pipes, chains, boats, anchors, and propellers. 144 dismantled ships were imported into the nation in 2020 as opposed to 236 in 2019.

Ships Scrapped Globally in First 3 Quarters of 2021

(In percentage)

No Data Found

The shipbreaking sector was severely impacted by the COVID-19 epidemic in its initial year, but according to the head of the Bangladesh Ship Breakers and Recyclers Association, there were no significant problems in 2021. Despite the prolonged shutdown, shipbreaking operations continued in 2021, and for the first nine months of that year, Bangladesh topped the global shipbreakers list. A total of 254 ships were brought in for scrapping in 2021. Still, 2021 saw a significant uptick due to a significant increase in imports, totaling more than eight million tons of disassembled metal.

- 20212728597 Tons

- 20221145324 Tons

- 20231022000 Tons

Bangladesh’s ship-breaking industry had a difficult year in 2023 as a result of the protracted currency crisis and a downturn in both the local and global economies. The nation imported the fewest scrap ships in ten years. The Bangladesh Ship Breakers and Recyclers Association reports that just 1,022,000 tons of scrap ships were imported in the previous year. This contrasts with imports of 1,145,324 tons in 2022 and 2,728,597 tons in 2021, even with the Covid-19 pandemic’s negative economic effects. For a lengthy period, no new Letters of Credit could be opened for the import of scrap ships from overseas due to the dollar crisis. As a result, the industry’s primary source of iron and steel output has decreased.

Initiatives Taken by the Government of Bangladesh for Bangladesh Ship Breaking Industry

The Shipbreaking and Recycling Rules, 2011

The Bangladeshi government enacted rules regulating this business in an effort to make shipbreaking a possible industry for the country. In January 2011, the Ministry of Environment and Forests released a Shipbreaking Guideline with the goal of achieving Environmentally Sound Management. On February 13, 2011, the Bangladeshi government officially recognized shipbreaking as a legitimate sector. “The Shipbreaking and Recycling Rules, 2011” was released by the Bangladeshi government to enhance the environmental and occupational health and safety standards in shipbreaking yards.

Bangladesh Ship Recycling Act 2018

After seven years, in 2018, the Bangladesh Ship Recycling Act came into force, following the Hong Kong Convention (HKC), which encourages firms in the country to use safe and environmentally conscious practices. The 2018 Act includes provisions for environmental preservation and ecological conservation. It also includes additional provisions dealing with workers’ rights, workplace safety and health, injury compensation, minimum wages and working hours, and so on. Within 2021, the government was required to establish a Treatment Storage and Disposal Facility (TSDF) for the waste management of ship reprocessing.

Green Industry

In order to guarantee that ships are recycled without putting additional risks to the environment or public health, the government set a new target of turning all ship-breaking yards into green facilities by 2023. Ships must go through two surveys before they may be recycled: one to examine the inventory of hazardous items, and another to do a final survey. The government of Bangladesh has taken the necessary steps to ensure that ship recycling yards publish a Ship Recycling Plan that outlines the specifics and inventory of each ship and how it will be recycled.

The shipyards are now being modernized under the supervision of the Bangladesh government. Three yards have previously gained “green yard” certification and 10 other yards are undergoing transformation. In Bangladesh, PHP Shipbreaking and Recycling Industries recently spent BDT 550 million and has complied with the Hong Kong Convention standards. In addition, enterprises at Sitakunda, like Khwaja Steel, SN Corporation, and Arefin Enterprise, are trying to establish a green shipbreaking yard.

Challenges of Bangladesh Ship Breaking Industry

Workplace safety issue

0

Worker deaths in 10 years

86.44% Employees

Without Access to Workers’ Compensation Insurance

Less than 2% Employees

Likely to receive healthcare

13% Employees

Under the age of 18

Around 86.44% of employees in this industry do not have access to workers’ compensation insurance. But the regular duties these labourers perform put their lives in grave danger. Explosions from gas leaks, workers crushed in steel beams, and heavy metal plates falling from tall decks are all too common. Over the previous ten years, 210 workers lost their lives in comparable circumstances. Depending on the situation, less than 2% of employees are likely to receive health care. Meanwhile, the prevalence of child labor in this industry is far higher. It’s estimated that at least 13% of all workers are under the age of 18. Shipbreaking yards pose a serious risk of dangerous conditions, especially for small children (Young Power in Social Action (YPSA) survey).

Chemical Exposure

Workers in the hazardous field of shipbreaking are constantly exposed to toxic compounds since they are not outfitted with the appropriate protective gear. Lead, cadmium, zinc, chromium, arsenic, and organotin are some of the elements present in paint used to coat steel ships that are destined for scrap. Because these substances cause inflammatory illnesses, there is a significant risk to the health of workers. The maritime ecosystem, animals, and human health are all at risk from these pollutants. In addition, the shipyards lack a sufficient waste management system to halt environmental deterioration. Since these harmful substances propagate locally, they represent a major risk to the ecology. However, shipbreaking trash seriously damages the ecology when it settles in the surrounding soil and shoreline area. World Bank (2010) found that polluted soil was found on beaches in Bangladesh. The environmental concerns associated with improper handling and disposal of hazardous materials during ship dismantling are signalled by this pollution.

Economic downturn and dollar crisis

The central bank instructed the commercial banks to give notice before extending large Letters of Credit for imports in July 2023, which led to further industry standstill. Shipbreakers noted that the distinctions between domestic and international markets are making it harder for business owners to turn a profit. They contend that while the price of scrap ships has been increasing on the international market, the closing of several steel and re rolling mills due to a shortage of raw materials has resulted in a decrease in the price of scrap steel on the local market. The current dollar scarcity makes it impossible for the sector to compete on the international stage.

Recommendations

- Shipbreaking companies should create a Ship Recycling Facility Plan (SRFP). The SRFP should show a strong dedication to environmental protection, worker health and safety, and knowledge and understanding of all relevant laws and regulations. The SRFP should also address the shipbreaking operating process and procedures.

- Introducing safety and health training, emergency response and evacuation, personal protective equipment, fire prevention and protection, handling and management of hazardous chemicals, information sharing, and environmental awareness training programs.

- In shipbreaking yards, it is challenging to prevent environmental contamination. On the other hand, pollution can be minimized. For shipbreaking, a “Containment Beaching Method” ought to be used in order to lessen environmental damage. The elimination of asbestos and broken heavy metal, sheet, and panel pieces should be packaged in leak-proof synthetic bags and disposed of at secured landfills. Before being disposed of, the bags should be mixed with cement to solidify them. Additional recommended actions include moist handling and removal of asbestos fibers and dust. The concentrations of asbestos fibers must be regularly monitored. These steps could reduce the environmental contamination caused by shipbreaking.

- The shipbreaking yards are required to adhere to international conventions when dismantling leftovers. Both the Hong Kong International Convention and the Basel Convention are well-known. The Hong Kong International Convention tackles the issues surrounding shipbreaking, including the potential for environmentally hazardous materials to be present in ships sold for scrap. It also addresses the concerns brought up regarding the working and environmental conditions at numerous ship recycling plants across the world.

References

- United Nations Conference on Trade and Development. (2018). Review of Maritime Transport 2018.

- International Maritime Organization. (2015). Global Casualty Statistics.

- Ahammad, Helal & Sujauddin, Mohammad. (2017). Contributions of Ship Recycling in Bangladesh: An Economic Assessment.

Cover Photo : By Naquib Hossain – https://www.flickr.com/photos/naq/4114723979/, CC BY-SA 2.0, retrieved from https://commons.wikimedia.org/w/index.php?curid=42076101

About the Author

A R Tahseen Jahan is the Co-Founder and Head of Policy at The Confluence. An undergrad student of Development Studies at the University of Dhaka, she worked on topics of economic development and public policy analysis.